The cost of 3D printing

Discover the key factors that make up the cost of 3D printed parts and learn how the different 3D printing processes and materials affect price.

Introduction

3D printing costs are a mostly a function of the type and amount of material required, and the type of printer chosen. Plastics are cheaper than metals, smaller parts use less material, and simpler or less robust parts can be printed with cheaper printers.

When considering different 3D printing processes and materials, many factors impact the decision – such as desired dimensional accuracy, surface finish, and post-processing requirements – all of which also influence the final cost.

So many combinations of these factors are possible when designing and manufacturing an individual part, including constant fluctuations in material costs, which can make it difficult to predict a price. A fast and accurate way to estimate the cost of a specific part is to upload your CAD to the Protolabs Network platform to receive a free and instant quote.

Skip to

The major factors influencing 3D printing costs

Assuming the design of a part is the same, the cost of 3D printing can be broken down into two main categories: material costs and equipment costs.

Material costs

- Base material

- Material waste

- Support structures ##### Equipment costs (outsourced or in-house)

- Installation and set-up time

- Running costs

- Periodic servicing

- Post-processing

- Maintenance and machine down-time Both the material and equipment costs are impacted by the 3D printing process. In the following sections of this article, you’ll find a cost comparison of the most common 3D printing materials and processes. The final section covers which aspects of your part design can have an influence on cost.

Cost of 3D printing materials

The choice of 3D printing material best suited for your application will dictate which 3D printing process you use. This is because different processes are compatible with different materials, as represented in the flowchart below.

Generally, 3D printed metals come at a much higher price point compared to plastics. 3D printed composites are usually more expensive than metals. In this section, we’ll summarize the costs of common 3D printing materials. You can find more details on material properties and pricing information in our Materials Index.

Plastics

3D printing plastics are divided into two categories – thermoplastics and thermosets. Thermoplastics, as the name suggests, are reactive to heat and can be melted, making them the most common material for material extrusion. Thermoset polymer resins are cured by UV light and are best suited for prototyping applications.

| Material | Description | Cost comparison |

|---|---|---|

| PLA | High stiffness, good detail, affordable. | $ |

| Resin | High detail and smooth surface, injection mold-like prototyping. | $$ |

| ABS | Commodity plastic, improved mechanical and thermal properties compared to PLA. | $ |

| Nylon | Used to substitute functional injection molded parts, good chemical resistance. | $$ |

| PETG | Good for mechanical parts with high impact resistance and flexibility. Sterilizable. | $ |

| TPU | Rubber-like material, suitable for tubes, grips, seals, and gaskets. | $ |

| ASA | UV stability and high chemical resistance, preferred material for outdoor applications. | $$$ |

| PEI | Engineering plastic, high performance applications, fire retardant. | $$$ |

| PC | Industrial thermoplastic with high accuracy, durability, and high strength. | $ |

Metals

Stainless steel and aluminum are the most common 3D printing metals but titanium and copper alloys are used for specialty applications. Laser melting, laser sintering, and binder jetting are all processes suited for 3D printing metal materials.

| Material | Description | Cost comparison |

|---|---|---|

| Stainless steel | High tensile strength, temperature and corrosion resistance. | $$$$$ |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. | $$$$ |

Composites

Composite materials such as carbon fiber, Kevlar, and fiberglass strands are at the forefront of 3D printing innovation. They offer strength properties similar to aluminum with an improved strength-to-weight ratio. Costs for composite materials can be 8-12 times the cost of plastic materials and 2-5 times the cost of metal materials.

In some applications, the cost of using composite material may be offset by the overall saving if less material per part is needed to achieve the same structural strength with a simpler design. Moreover, a hybrid approach could be considered for a part that combines composite material with metals and/or plastics. Composite 3D printing materials are common in specialty industries where reducing weight takes precedence over reducing cost, such as aerospace, medical, alternative energy, and high-performance automotive.

Costs by 3D printing process

See below for a comparison of the different factors that contribute to the overall cost for common additive manufacturing processes.

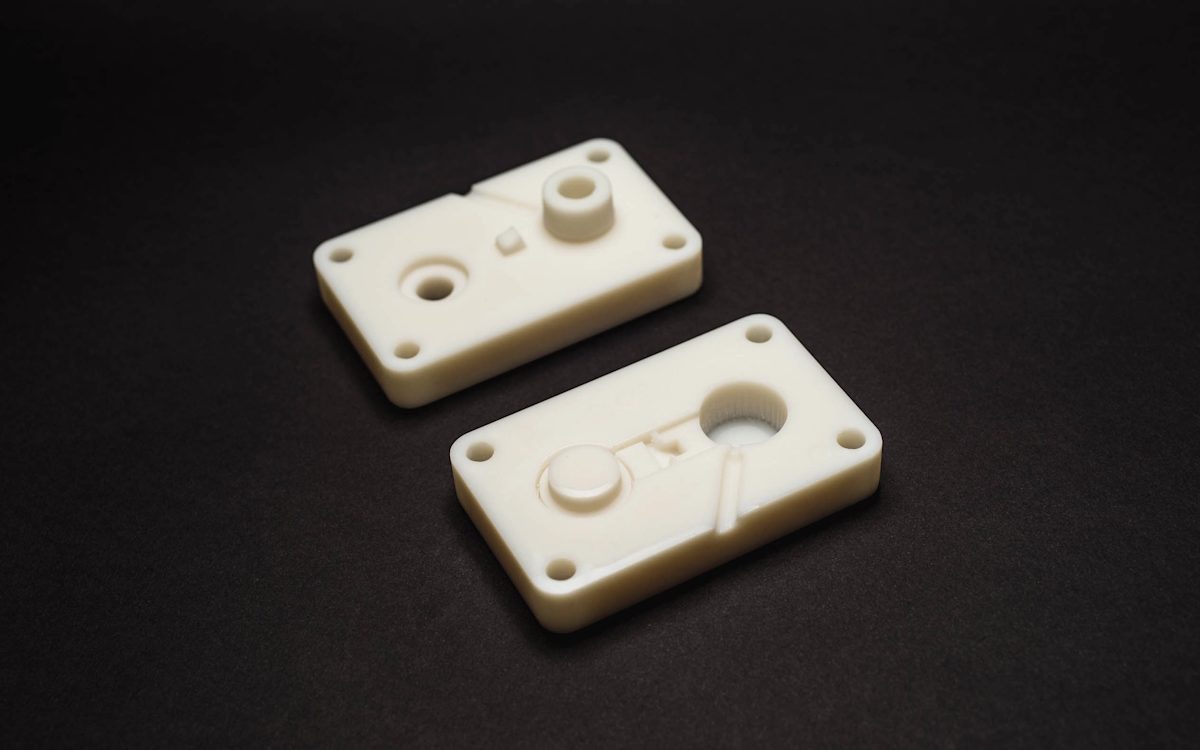

Material extrusion

Includes: Fused Deposition Modeling (FDM, pictured)

Lowest cost for simple part geometry and smaller batches.

Material costs:

- Lowest base material cost

- Cost of support structures generally increases with part complexity

Equipment costs:

- Low costs due to part set-up time

- Overall costs increase as part complexity increases due to higher post-processing time/labor

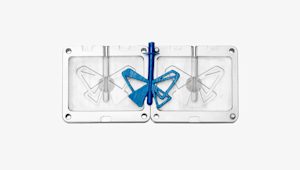

Vat photopolymerization

Includes: Stereolithography (SLA, pictured), Digital Light Processing (DLP), Continuous DLP (CDLP)

Can produce more complex part geometry and higher-volume batches. Higher material costs but lower post-processing costs.

Material costs:

- For plastics, highest overall material costs compared to material extrusion and powder bed fusion

Equipment costs:

- Lowest part set-up time

- Lower costs for post-processing due to high surface quality of parts

Powder bed fusion

Includes: Selective Laser Sintering (SLS, pictured), Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), Multi Jet Fusion (MJF)

Lowest overall cost for complex part geometries, higher-volume batches, and high-quality part finishes.

Material costs:

- Base material cost is typically higher than material extrusion but lower than vat photopolymerization

- No support structure reduces overall material costs

- Base material can be reused which minimizes waste and reduces material costs

Equipment costs:

- Higher part set-up time and maintenance between batches to handle powder material

- Lowest costs for post-processing due to lack of support structures

Material jetting

Higher overall cost compared to material extrusion but lower overall cost than processes using laser melting/sintering.

Material costs:

- Similar to vat photopolymerization

- Highest overall material costs compared to material extrusion and powder bed fusion

Equipment costs:

- Lowest part set-up time

- Support structures required for most parts, cost increases with complex geometries

- Lower cost for post-processing due to high quality part finish

Binder jetting

Lower cost compared to material jetting due to decreased material volume and time to print. May be a cost-effective solution when high-quality finish, part geometry details, or material properties are not a design priority.

Material costs:

- Higher base material costs – similar to laser melting/sintering

- No support structure reduces overall material costs

Equipment costs:

- Higher cost for post-processing if high-quality finish, part geometry details, or material properties are a design priority

- Higher part set-up time and maintenance between batches to handle powder material compared to material jetting

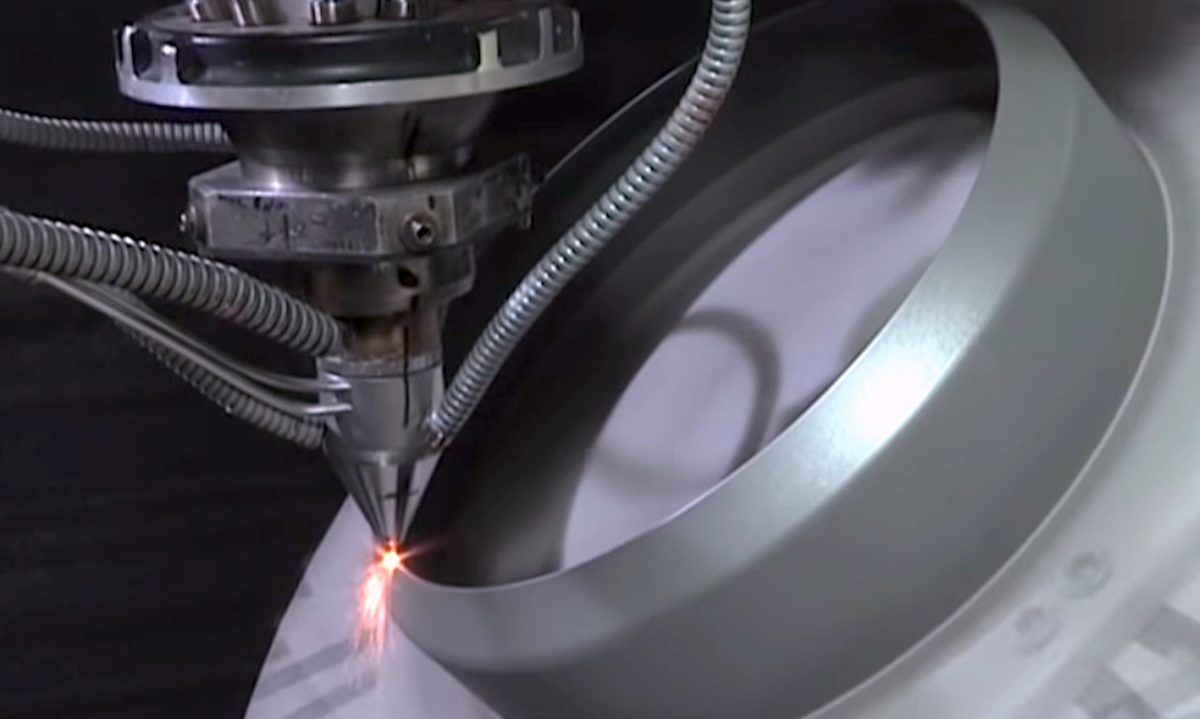

Directed Energy Deposition

Includes: Laser Engineered Net Shaping (LENS), Direct Metal Deposition (DMD), Electron Beam Additive Manufacturing (EBAM)

Similar overall cost to laser melting/sintering and powder jet fusion.

Material costs:

- Higher base material costs – similar to powder bed fusion and laser melting/sintering

- Higher cost due to material waste for complex part geometries

Equipment costs:

- Higher cost for post-processing for complex part geometries

- Higher part set-up time and maintenance between batches to handle powder material

How design affects 3D printing costs

Long before a part is ready for printing, design decisions will directly impact the overall cost including total material, support structures, and required post-processing. Key design considerations that affect cost are summarized below:

Part volume

The total volume of the part matters, a small reduction in the size of the model can greatly reduce the cost of the 3D printed part.

Support structures

Material costs, due to support structures, vary based on the 3D printing process. If the design can be printed using different methods then the cost of print may be reduced.

- Material extrusion and material jetting usually require more support structures as part complexity increases.

- Powder bed fusion does not require support structures and reduces overall material costs.

### Part geometry Part geometry can reduce material required for support structures. To reduce costs, consider splitting the part model into multiple parts, reducing the length or angle of overhangs, or reorienting the model within the printing base.

### Infill Infill is typically required to maintain part shape but increases material costs. If strength or material density are design priorities then consider optimizing infill design to reduce material costs.

### Post-processing Layer thickness does not significantly impact the overall material cost of a 3D printed part; however, the cost of post-processing may be impacted if a high quality finish is required.

For more details, see our guide [how to reduce 3D printing costs](https://www.hubs.com/knowledge-base/how-reduce-cost-3d-printing/).