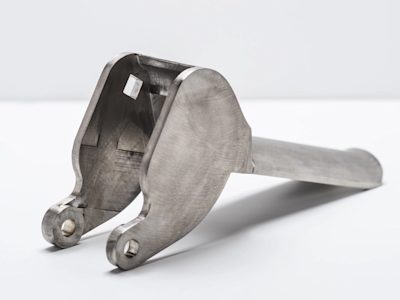

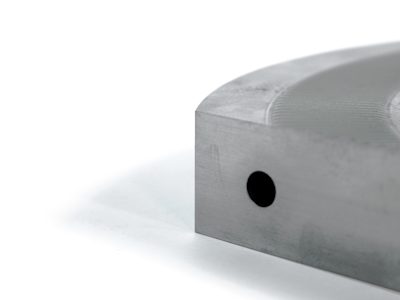

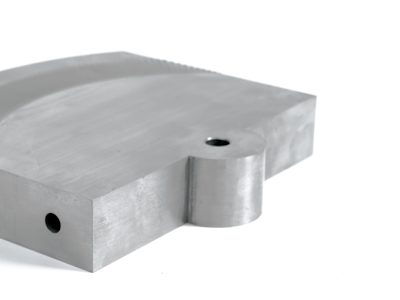

High hardness CNC machining

Metals with hardness > 300 HB (> 32 HRC). Ideal for applications that demand excellent wear resistance.

Description

Description

Characteristics

Characteristics

$ $ $ $ $

Available materials

Available materials

Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

Alloy steel 4140 (CNC) has good overall properties, with good strength and toughness. Suitable for many industrial applications. Not weldable.

Learn more Get instant quoteTool steel D2 | 1.2379 | X153CrMoV12-1 - Annealed state

Tool steel D2 (CNC) is a wear-resistant alloy that retains its hardness to a temperature of 425 °C. Used for cutting tools and dies.

Learn more Get instant quoteTool steel A2 | 1.2363 | X100CrMoV5-1- Annealed state

Tool steel A2 (CNC) is an air-hardened general purpose tool steel with good toughness and excellent dimensional stability. Used for molding dies.

Learn more Get instant quoteAlloy steel 4340 | 1.6511 | 36CrNiMo4 | EN24

Alloy steel 4340 (CNC) can be heat treated to high strength, while maintaining good toughness, wear resistance and fatigue strength. Weldable.

Learn more Get instant quoteTool steel O1 | 1.2510 | 100MnCrW4 - Annealed state

Tool steel O1 (CNC) is an oil-hardened alloy with a high hardness of 65 HRC. Used for industrial knives and cutting tools.

Learn more Get instant quoteStainless Steel 17-4 PH | 1.4542 | X5CrNiCuNb16-4 - Annealed state

Stainless steel 17-4 (CNC) - SAE grade 630 - is a precipitation hardening alloy with good corrosion resistance. Can be hardened up to 44 HRC.

Learn more Get instant quoteStainless steel 2205 Duplex | 1.4462 | 2205 | X2CrNiMoN 22-5-3

Stainless steel 2205 Duplex (CNC) is the alloy with the highest strength and hardness. Suitable for applications in severe environments up to 300°C.

Learn more Get instant quote